Why Use Fiber Duct Versus Sheet Metal

We see to much duct board falling apart at the joins with nasty mold growing in it.

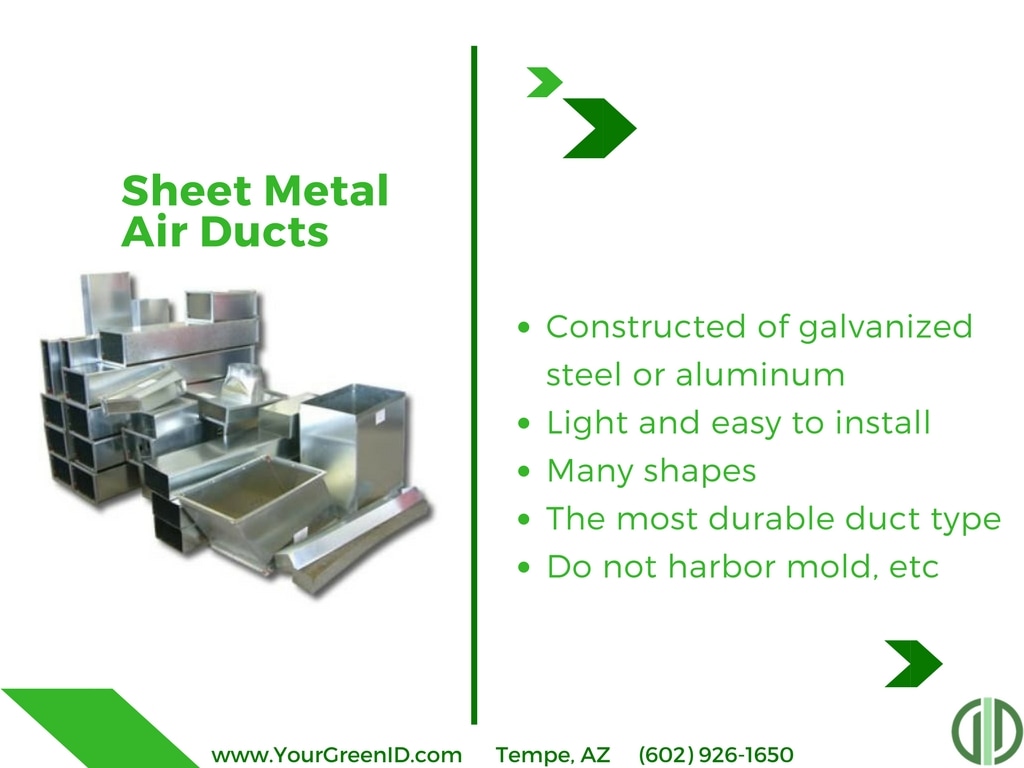

Why use fiber duct versus sheet metal. Duct joints should always be secured with 8 sheet metal screws before seams are sealed with mastic. One of the major advantages of sheet metal ductwork is its staying power. We use all metal duct with wrap on the outside only. Metal ducts are more rigid due to the nature of steel making them ideal to build an entire hvac system.

Sheet metal friction is based on surface and joint. Metal metal do it once and do it right. The mastic is spread over duct seams with a disposable paintbrush putty knife or. Flex ducts are better for existing trunk and branch heating and cooling systems.

Because of what it s made out of it tends to last a long time especially when it is properly cared for. As a rigid material your sheet metal ductwork needs to have adequate space. Made from compressed fiberglass strands which are bonded with resin and covered with a foil laminate for moisture protection. In comparison to metal duct flex duct is easier and faster to install.

This is because they re more versatile and flexible. The blue curve is the sheet metal curve the green curve is that of unfaced or finished duct board and the yellow is our best estimate of the desi gn values for the laminate faced new generation duct board product. Fiberglass lining is used to insulate air ducts from heat loss or to avoid condensation in cases where the supply air is very cold or there is a high ambient humidity in the plenum. Made from sheet metal ducts with internal and external fiberglass lining.

Use to design the duct systems. These three curves are shown in figure 1. N in fibergl removal before and after page 3 duct flow wikiwand fibergl conduit hangers champion bridge fibergl conduit hangers champion bridge n in fibergl removal before and after page 3 harold r whelden heating refrigeration. We also use third party cookies that help us.

Sealing duct seams is messy work so wear old clothes. I have never liked duct board or ducts lined with fiberglass. As for metal v flex for taps thats your call metal is better but flex is fine. The most common materials used for sheet metal ducts are aluminum and galvanized.

Some sheet metal air ducts are lined with an external or internal fiberglass duct liner. The idea of the porous insulation on the interior just doesn t seem like a good idea. Mastic is a gooey non hardening material with a consistency between mayonnaise and smooth peanut butter.